HYBRID ENGINE SYSTEMS

Over the course of ten years, the Sounding Rocketry Team (SRT) has designed, built, and tested six different flight-ready hybrid engines. Our engines have been designed from the start to be integrated into existing or developmental vehicles created by SRT. Additionally, each engine is tested through routine static engine firings at a team-maintained vertical test cell. All engines built by SRT are pressure-fed. Propulsion team members go through a rigorous design and testing (hydrostatic) process to ensure these engines are safe to operate as well as meet the performance specifications outlined by overall team goals.

Scroll down to learn more about our current engine, Hyperion, and our past engines Vulcan, Nova, Icarus, Helios, and Alpha.

Scroll down to learn more about our current engine, Hyperion, and our past engines Vulcan, Nova, Icarus, Helios, and Alpha.

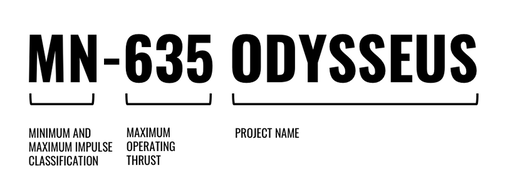

Engine Classification

|

SRT follows a similar naming convention to those used by the Tripoli Rocketry Association (TRA) and the National Association of Rocketry (NAR) for engines created by the team.* Certified commercial motors use a leading letter indicating the impulse class followed by a number specifying the average thrust of the motor. For more information as to how TRA and NAR name certified engines & motors please visit the NAR website page.

|

Minimum and maximum impulse defines the theoretical impulse range of a given engine design. Engines are typically designed to operate in the middle of their range. The operating peak thrust is the highest thrust the engine will deliver in its intended operating configuration. Project name is given to the design by the creating year. Version roman numeral denotes major design changes. For example, a particular engine may be fitted with a brand new injector design. This configuration will now be described as a new version of the original design.

*Engines built by SRT are considered "research" propulsion systems by TRA and are not certified*

NO-750 Hyperion

|

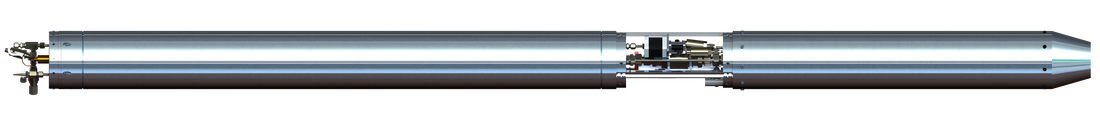

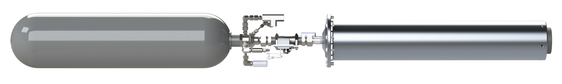

NO-750 Hyperion Hybrid Engine

|

Hyperion is the SRT-10 designed 30,000ft capable hybrid rocket engine. A completely new design, Hyperion is designed to fit in a smaller 6in rocket diameter and comes with an increase in tank length, increase in chamber length, solid-ignition system using potassium nitrate, and a stepper motor actuator with a gear train. Hyperion also contains the first ever in house designed pressure vessel.

|

Design Team: SRT-10 (2022-2023)

Build Team: SRT-10 (2022-2023) Modified: N/A Versions: 1 Vehicle: Odysseus Engine Type: Hybrid Oxidizer: Nitrous Oxide (N2O) Fuel: Hydroxyl-Terminated Polybutadiene (HTPB) |

Pressurization Method: Self-pressurized

Injection Method: Vortex Injection, Impinging Injection Peak Thrust: 750 lbf Theoretical Impulse: 7800 lbf-sec Theoretical Specific Impulse: 219 sec Hydrostatic Tests: TBD Cold Flow Tests: TBD Static Engine Tests: TBD |

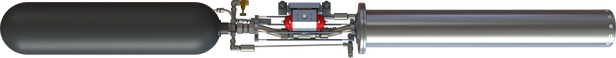

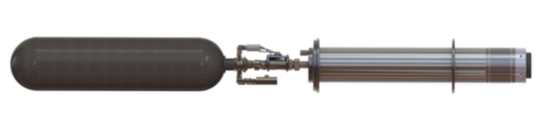

NP-850 VulcanNP-850 Vulcan Hybrid Engine

Vulcan is the SRT-7 designed 30,000ft capable hybrid rocket engine. An iteration on the previous Nova design, Vulcan comes with an increase in tank size, increase in chamber length, solid-ignition system, commercial off-the-shelf pneumatic ball valve actuation system, and manual venting capabilities. Grain additive development and testing for this engine will increase impulse and overall thrust to reach 30,000 ft for IREC 2022.

|

NP-915 Nova

NP-915 Nova I Hybrid Engine

Nova was designed, constructed, and tested under SRT-5. The engine features a modified injector housing, standardized aluminum plumbing lines, an upgraded sensor suite, an additive-mixed fuel grain, an improved regression rate, and an optimized thrust profile over the NP-915 Icarus II engine.

|

Design Team: SRT-5 (2017-2018)

Build Team: SRT-5 (2017-2018) Modified: SRT-6 Versions: I & II Vehicle: Theseus Engine Type: Hybrid Oxidizer: Nitrous Oxide (N2O) Fuel: Hydroxyl-Terminated Polybutadiene (HTPB) |

Pressurization Method: Self-pressurized

Injection Method: Vortex Injection; Impinging Injection Operating Peak Thrust: 675 lbf Operating Impulse: 3450 lbf-sec Operating Specific Impulse: 217 sec Peak Thrust Prediction Efficiency: 0.92-0.95 Impulse Prediction Efficiency: 0.95-0.99 Hydrostatic Tests: 7 Cold Flow Tests: 2 Static Engine Tests: 6 |

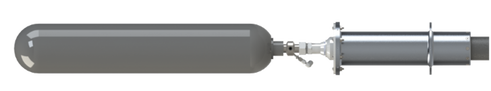

NP-915 Icarus

NP-915 Icarus II Hybrid Engine

Icarus was the largest and most powerful hybrid engine built and tested by SRT. There are two versions distinguished by the injector design used. The engine features a light-weight composite tank (Luxfer), custom ball-valve actuation system, removable coin injector system with vortex injection, and a cubic graphite nozzle. All fittings are 304/316 Stainless Steel, while the injector and combustion chamber are made from 6061-T6 Aluminum.

|

Design Team: SRT-3 (2015-2016)

Build Team: SRT-3 (2015-2016) Modified: SRT-3 (2015-2016) SRT-4 (2016-2017) SRT-5 (2017-2018) Versions: I & II Vehicle: Daedalus Engine Type: Hybrid Oxidizer: Nitrous Oxide (N2O) Fuel: Hydroxyl-terminated polybutadiene (HTPB) |

Pressurization Method: Self-pressurized

Injection Method: Swirl Injection; Axial Injection Operating Peak Thrust: 560 lbf Operating Impulse: 3550 lbf-sec Operating Specific Impulse: 212 sec Peak Thrust Prediction Efficiency: 0.95-0.99 Impulse Prediction Efficiency: 0.95-0.98 Hydrostatic Tests: 20+ Cold Flow Tests: 3 Static Engine Tests: 8 |

LN-350 Helios

LN-350 Helios Hybrid Engine

Helios was the second engine developed by SRT in two years. There are two major versions of this design distinguished by the oxidizer flow control and injector design. The oxidizer flow control is directly interchangeable with the NP-915 Icarus engine system. The engine features a light-weight composite tank (Luxfer), custom ball-valve actuation system (Vers. II), removable coin injector system, and a cubic graphite nozzle. All fittings are 304/316 Stainless Steel, while the injector and combustion chamber are made from 6061-T6 Aluminum.

|

Design Team: SRT-2 (2014-2015)

Build Team: SRT-2 (2014-2015) Modified: SRT-3 (2015-2016) SRT-4 (2016-2017) Versions: I & II Vehicle: Phoenix Engine Type: Hybrid Oxidizer: Nitrous Oxide (N2O) Fuel: Vers. I: Nylon 6/6 Vers. II: Hydroxyl-terminated polybutadiene (HTPB) |

Pressurization Method: Self-pressurized

Injection Method: Impinging Injection; Axial Injection Operating Peak Thrust: 350 lbf Operating Impulse: 2281 lbf-sec Hydrostatic Tests: 10+ Cold Flow Tests: 5 Static Engine Tests: 5 |

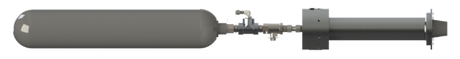

LN-350 Alpha

LN-350 Alpha Hybrid Engine

Alpha was the first engine designed, built, and tested by SRT during its first year in existence. Many of the sub-systems tested on this design were optimized and incorporated into later designs. Alpha featured a light-weight composite tank from Luxfer (tested with aluminum tanks), chain-and-sprocket actuated ball valve, and cubic graphite nozzle. All fittings are 304/316 Stainless Steel, while the injector and combustion chamber are made from 6061-T6 Aluminum.

|

Design Team: SRT-1 (2013-2014)

Build Team: SRT-1 (2013-2014) Modified: N/A Versions: I Vehicle: Valor Engine Type: Hybrid Oxidizer: Nitrous Oxide (N2O) Fuel: Hydroxyl-terminated polybutadiene (HTPB) |

Pressurization Method: Self-pressurized

Injection Method: Impinging Injection; Axial Injection Operating Peak Thrust: 350 lbf Operating Impulse: 2598 lbf-sec Hydrostatic Tests: 5 Cold Flow Tests: 1 Static Engine Tests: 2 |

STAY CONNECTED WITH US